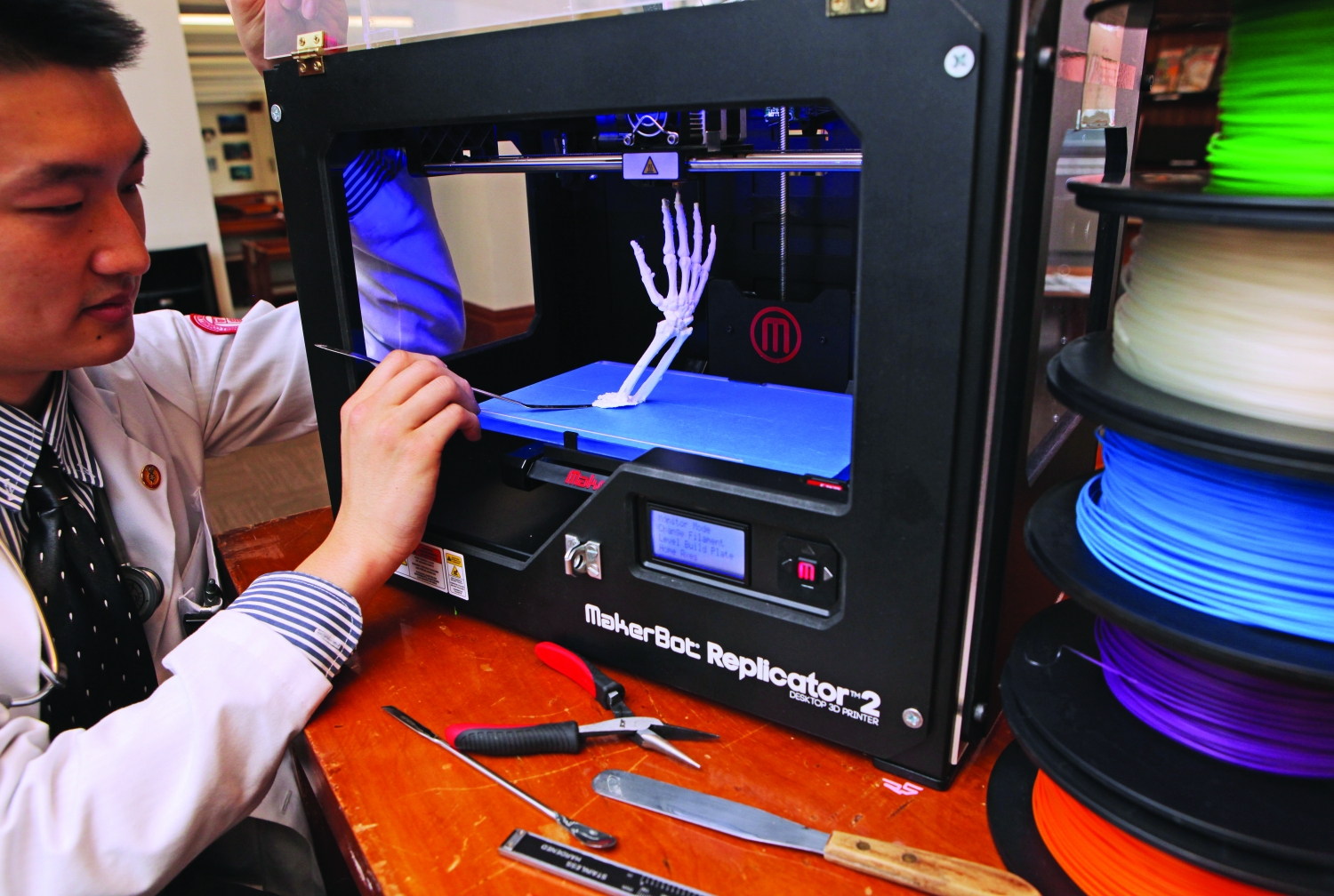

The library's new open-access 3D printer gets rave review

In the spring of 2014, first-year M.D.- Ph.D. student Du Cheng brought a bone fragment from an anatomical model to Dr. Estomih Mtui. Cheng told Dr. Mtui, a professor of anatomy of radiology, that he'd found the fragment, part of a facsimile of the fourth lumbar vertebrae that had gone missing from the lab.

That was a fib: Cheng had actually created the piece using a 3D printer, a demo model he'd seen in a store. But he wanted to test the machine's prowess, so he passed it off to Dr. Mtui as the real thing. The professor slipped the bone model in place — and it fit. Only then did Cheng reveal that the crucial bit had been printed for mere pennies. As Cheng recalls it: "I said, 'Oh my God — you didn't realize that producing this only cost 25 cents!'"

In summer 2014 — fueled in part by that success — Cheng convinced Weill Cornell Medicine to purchase a 3D printer for general use, and he has since formed a user's group that now includes more than 100 people. The printer is in the library — Cheng says he enjoys watching tour groups of prospective students stop and admire it — and is available to members of the Weill Cornell Medicine community who complete a training class with the student group DimensionWorks for Biomedical Design, of which Cheng is president.

As work at Weill Cornell Medicine and elsewhere has shown, 3D printing technology has the potential to revolutionize medicine, notes Dr. Francis Barany, a professor of microbiology and immunology. In a collaboration between Weill Cornell Medicine and the Ithaca campus, for example, researchers are creating 3D printed ears made from living tissue that could be implanted in patients who lack them due to a congenital defect. "Every human is different, so the ability to print something that can be put into the body is very exciting," Dr. Barany says. "3D printing is a baby right now. Who knows how it's going to grow up?"In 3D printing, a user designs an object using a computer program; the printer then creates it by extruding one thin layer of plastic on top of another, building it up into the desired shape. The technology is already having a positive impact on research, says Jonathan Witztum, a doctoral candidate in physiology, biophysics and systems biology. For example, Witztum recently needed a special kind of imaging chamber to study brain tissue for his thesis. "Having the printer on campus shortened the time it took to design and perfect the chambers we use," Witztum says. "Making it available to everyone has a great impact on people's work." The printer has fostered a number of other projects, Cheng says. It has been used to create a specialized platform for a microscope that would otherwise cost thousands of dollars; to make models of bone marrow for pediatric research; to create a fixation device for researchers imaging the brains of mice; and more.

— Jeff Stein

This story first appeared in Weill Cornell Medicine,Vol. 14, No. 2.